joint laboratory inspection

Metallurgical Engineering Services operates as a third party laboratory to ensure fair and objective testing in a functional and comfortable setting. Our spacious 14,000 square foot facility provides state-of-the-art test instrumentation at your disposal. Our numerous inspection, machining, and test laboratories provide ample room for laboratory inspection, sample dissection and specimen preparation. Let MES assist you with unbiased litigation support.

Our FACILITIES

Located in the heart of the Dallas-Ft. Worth metroplex and convenient to either DFW airport or Love Field, our Dallas facility occupies over 14,000 square feet of laboratory facilities. Our open floor plan is optimum for hosting both independent and multi-party inspections of any size. Our Richardson facility is a one-stop-shop for your next joint inspection. We provide expert service for all your mechanical, inspection, and metallurgical testing needs.

Our Team

With over 30,000 analytical projects completed, the MES staff consists of experienced professionals in the disciplines of materials science, electron beam surface characterization, mechanical, and metallurgical engineering. Our depth of experience allows us to offer unparalleled service for your litigation support.

Modern Equipment

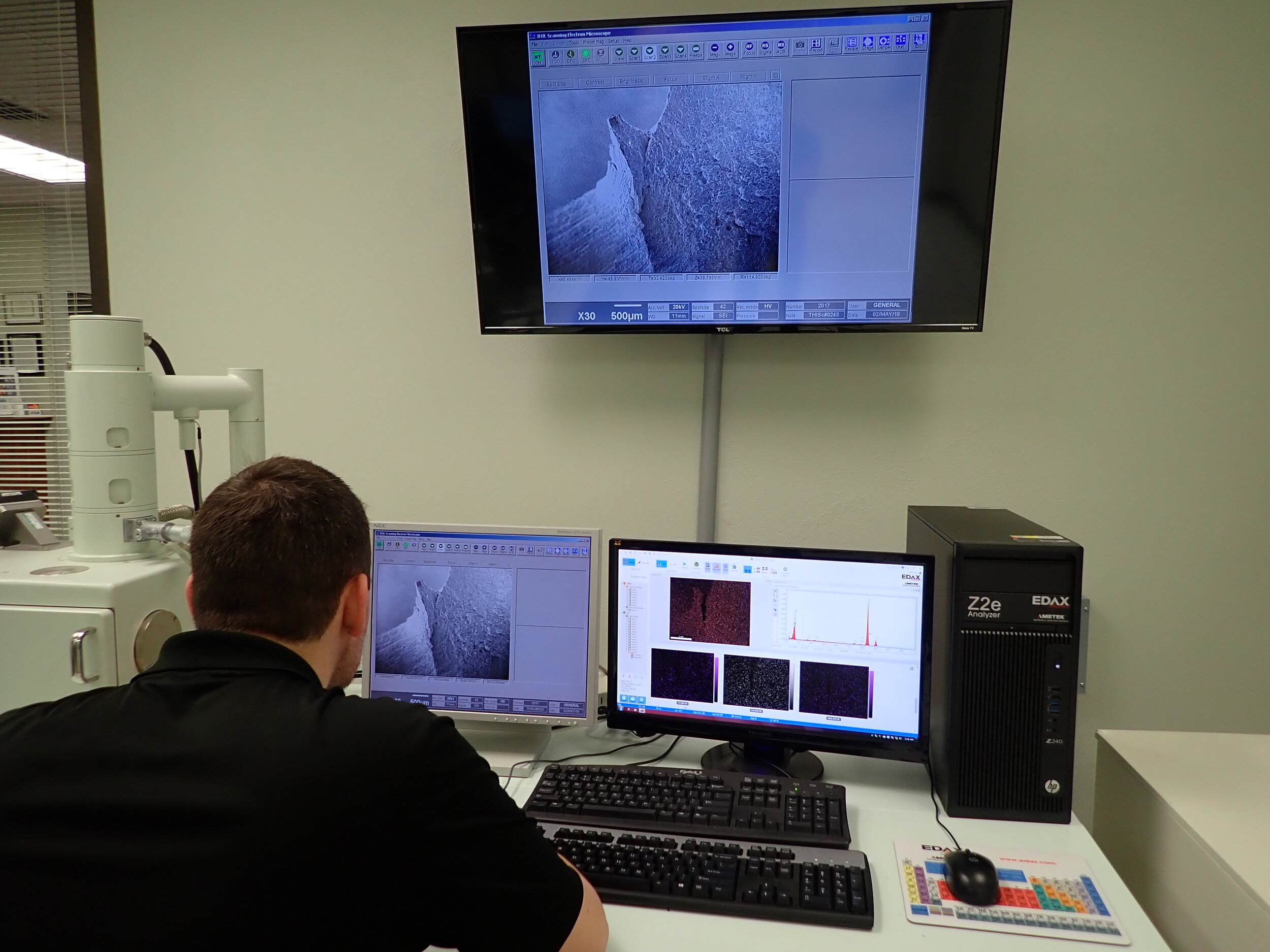

Zeiss HD-15 Scanning Electron Microscope

Leica DMS 1000 Digital Light Microscope

Leica Optical Stereoscopes

JEOL 6460-LV Scanning Electron Microscope

Thermo Fisher Dry Energy Dispersive X-Ray

Full Metallographic Laboratory

Machine Shop with Haas CNC Machining Tools

Mechanical Test Laboratory with all ranges of Tensile, Hardness, Pressure and Impact Testers

NDT Test Laboratory with Level II Inspectors for Radiography, Ultrasound, Dye -Pen, Eddy Current, and Mag-Particle

Amenities

Large Screen Video Displays for Microscopes

Upscale, Large Conference Room

Functional sample preparation and breakdown tables

Secure, Climate-Controlled Evidence Storage Rooms

Multiple Conference Rooms

Secretarial support

Wi-Fi internet access